Convert Eplan To Autocad

AutoCAD Elec to EPLAN Conversion Conversion of AutoCAD Electrical drawings to EPLAN format, no design work, just a straight like for like copy of existing design. Please contact me ASAP for more information, I need quotes urgently as part of costing process, though job is not for a few months. From AutoCAD to Eplan P8 Eplan consultants. Dear Sir, I am working in ABB Riyadh. We are using Eplan as our electrical schematic drawing tool. We need to convert our files from Eplan to microstation(DGN). But we cannot go directly first we have to go throught autocad then microstation. Convert Autocad To Eplan, free convert autocad to eplan freeware software downloads. How to import a STEP file into AutoCAD products? Do the following from within AutoCAD: Type IMPORT in the command line. Locate the folder containing the STEP file. Select the file and click OK. A window might pop up indicating that the import process is working in the background. In the lower right corner of AutoCAD, a notification message will pop up, indicating that the import.

I was recently involved in a fair sized project conversion (200+ pages) from AutoCAD to EPlan P8. I was helping this customer on their very first Eplan project which would eventually become their “template” for future machines.

Convert Eplan Into Autocad

/stata-13-free-download.html. What struck me, once again, is that most people coming from AutoCAD tend to concentrate on the graphical aspects of their documents, while giving less consideration to the logical aspects of it. Having worked with AutoCAD for many years myself, I definitely understand why it is so. AutoCAD is a very good drafting software, but when it comes to expressing electrical schematics, it falls flat for anything but the most trivial project. The lack of specialized tools in AutoCAD makes it so that drafters will leave out details that would guide the panel builders in their job, only to shift that responsibility on those same panel builders. One good example of this is leaving out the terminals from the schematics because “our guys on the shop floor know where to put them as needed”.

Not only does this shift responsibility to the wrong place, but it raises the labor cost when errors are discovered and panel builders/shop workers lack the knowledge to correct them. We then assist to a merry-go-round between shop floor, drafters and engineers, and a simple one hour thing ends up eating up a man-day of labor.

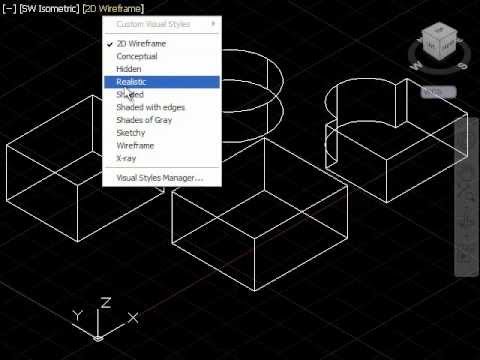

This is definitely a mistake when working with EPlan, which is more of a design tool than a drafting tool. In EPlan, as you create your electrical schematics, you’re not only laying out graphical elements on the page, you’re actually building a “model” of you machine’s controls. The analogy I always give at my trainings is that of using AutoCAD vs. 3D modeling software for mechanical design. In the old days of 2D drafting, modifications to one drawing often involved many manual updates on several other drawings to reflect all the views of the object. Countless errors came from forgotten updates, and many manufactured parts had to be scrapped because of this.

With the advent of 3D modeling software such as Inventor or SolidWorks, you concentrate on modeling the actual part, and you generate views as needed. Any needed changes are done on the model itself, and views are regenerated, making sure that nothing is forgotten. This brings consistency and quality to the design. Shop workers are free to do their jobs instead of wasting time trying to understand discrepancies between drawings.

When applied to the electrical engineering field, modeling your controls is a definite advantage over “dumb” graphical entities. Once the model is completed, you can project “views” in the form of reports that give you all the needed documents for you production team. For example, you can extract a bill of material, a list of wires, terminal diagrams and so on. You know that these generated documents will be consistent and error free as long as you maintain your model error free.

One typical source of errors in electrical schematics is the manual handling of cross-references. For example, a relay coil will typically be represented on one page, and its contacts on different pages. Trying to maintain this information manually is tedious and error prone. The same goes for interruption points that transmit your power rails between pages. This automated cross-referencing in EPlan alone is well worth the cost of the software !

Another benefit of modeling your controls is that it forces the designer to actually think about what he’s doing as opposed to a drafter who’s content with executing the red-lining given to him by the engineers. This is most apparent in the routing of your circuits within your electrical enclosures.

Let’s give an example of this. Here’s a typical AutoCAD way of representing schematics:

This is an IEC style schematic where we see some relays, a door mounted pilot light, and a field mounted pilot light. The problem with this representation is that it gives absolutely no clue to the panel builder about the routing of the wires. If we were to follow the circuit naively, we would go from relay K2 to relay K3, to the door, then to the field, and finally back to the enclosure to relay K4. This would of course be a very inefficient way of wiring this circuit because we’d have to bring two wires to the pilot light in the door, and two wires to the one in the field.

This is where the knowledge of how to build the machine is shifted from the engineering department to the production floor. We rely on the experience of a few individuals within the company who have informal knowledge of how to wire your machines. If they should ever retire or leave the company, or even if you were to outsource your production, you’d be hard pressed to come up with this knowledge.

On the other hand, here’s the same schematics reworked in EPlan:

First we notice that components have been reordered to better express the real routing of the wires. Obviously, we want to daisy chain the neutral on those relays before going out to the door and field. Also, we show the actual terminals to connect external components. Finally, we notice the use of T-Nodes instead of points to better express the routing.

From such a model of the circuit, we could easily generate a list of wires with their respective source and destination, and the panel builder team would simply have to blindly follow it.

Convert Eplan To Autocad Electrical

So in the end, when converting AutoCAD schematics to EPlan, it’s not only a matter of making sure that the graphical aspect of the wiring is done, but there is also a lot of thought that must be given to the logical aspects. Now that%27s what i call music 100 download torrent. This will of course involve spending more time in the design phase, but what I’ve seen is that this time consistently pays for itself down the line.

Convert Autocad To Eplan

If you need someone to convert your AutoCAD schematics to EPlan, don’t hesitate to contact us for expert consulting on how to best achieve this.